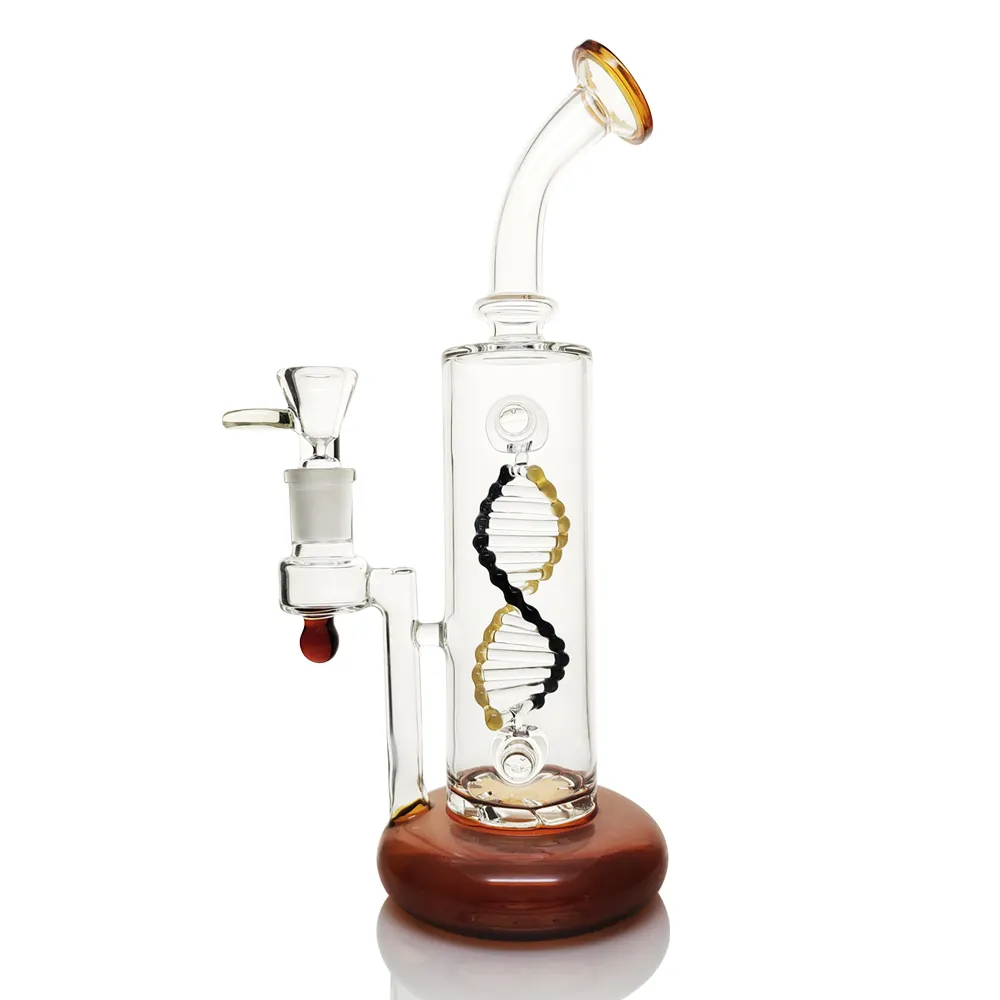

As the global popularity of hookah smoke continues to rise, the demand for innovative hookah accessories, high-end hookah parts, and reliable hookah manufacturer partners has reached unprecedented levels. Gene sequence hookah stands at the forefront of this evolution, blending precision engineering, advanced materials, and bespoke customization. This article explores industry trends, technical breakthroughs, application scenarios, and tangible business value.

- The global hookah smoke market was valued at $1.8 billion in 2023, with a projected CAGR of 8.9% through 2028. [Source: IMARC Group]

- Consumers are increasingly demanding high-durability hookah accessories and modular hookah parts to tailor their experience.

- Environmental compliance, safety (FDA/ISO certification), and long service life have become key purchasing decision factors for B2B buyers and lounges.

| Parameter | Gene Sequence Hookah | Standard Hookah | Test Method |

|---|---|---|---|

| Body Material | High-borosilicate glass + 304SS (CNC/forged) | Aluminum Alloy / Glass | ISO 9227: Corrosion Testing |

| Accessory Modules | Modular, quick swap (mouthpiece/valve/base/hose) | Fixed/limited modules | ANSI B46.1: Interchangeability |

| Surface Finish | Electropolished internals, ≥Ra 0.3μm | Brushed/polished, Ra 0.7μm+ | ISO 4287: Surface Texture |

| Heat Resistance | Up to 600°C sustained, no deformation | 300-400°C (glass distortion possible) | ISO 7438: Heat endurance |

| Smoke Delivery Consistency | ±3% airflow deviation at 0.01 MPa | ±9% deviation (typical) | EN12327: Gas tightness |

| Corrosion Resistance | 600h+ in 5% salt-spray test | 200h-350h typical | ASTM B117 |

| Certifications | ISO 9001:2015, FDA contact safe | Often uncertified | 3rd Party Lab |

| Warranty | 2 years (manufacturer backed) | 0-1 year | Hookah manufacturer policy |

Gene Sequence Hookah Manufacturing Process:

- Raw Material Selection(Certified borosilicate glass & 304 Stainless Steel) →

- CNC Precision Machining (Mouthpiece, Valves, Connectors; Tolerance <0.05mm) →

- Glass Blowing & Annealing(Thermal stress relief at 580°C) →

- Surface Treatment(Electropolishing, Coating, Decorative) →

- Assembly & Leak Testing(Full ISO 9001 QA traceability) →

- Packaging & Labeling(Custom branding, serial # tracking)

- Materials: Fully customizable: high-borosilicate, Pyrex, SS304, SS316L, PEI/Ultem for specialty use

- Dimensions: Heights: 28–65cm; Chamber volumes: 450–1500ml; Mouthpiece bore: 9–20mm

- Surface/Color: Frosted, clear, iridescent, hand-painted; PMS-matched colorways supported

- Branding: Company logos, engraved marks (laser/hand), serialized QR-tracking

- Accessories: Hose types, LED bases, diffuser heads, modular add-ons, anti-backflow valves

- Premium Hookah Lounges: Modular hookah accessories allow for rapid customization and easy cleaning between sessions, ensuring hygiene and memorable guest experiences.

- Hospitality Chains: Uniform branding & anti-tamper valves meet safety codes (ISO/EN standards), while robust hookah parts lower annual replacement costs by 45%.

- Chemical / Petrochemical Testing: Heat and corrosion-resistant chambers enable sample testing in R&D labs (relevant for ISO/ASTM compliance studies).

- Event Management: Quick-assemble systems support high-volume, mobile use with full compliance—reducing setup time by 33% compared to competitors.

- “After 9 months of daily use, zero visible corrosion and 100% airtight. We now specify Gene sequence hookah for all our venues.” – Global Cafe Group, Dubai

- “As a hookah manufacturer we tested 7+ suppliers. DSGene beat all with consistent finish quality and incredibly robust hookah parts.” – Euro Tech Import

- “The modular accessories and ease of cleaning reduced our maintenance labor by 38%.” – VIP Lounge (NYC)

- Years of Experience: 17+ years as a dedicated hookah manufacturer, supplying to over 41 countries

- Industry Certification: All systems ISO 9001:2015, with FDA, CE, RoHS compliance

- Reference Partners: Service to Sheraton, Hilton, MAKL Group, Global Shisha Events

- Traceable QA: Serial tracking, 100% pressure-tested prior to packaging

- Innovation: Proprietary multi-chamber design for even hookah smoke & flavor consistency

- Lead Time: Standard items: 5-12 working days. Large batch/fully customized: 17–32 days upon drawing approval.

- Shipping: Air (FedEx/UPS/DHL), sea-freight, or to bonded warehouse per client needs.

- Warranty: 2 years full manufacturer defect coverage. Optional 3rd year extended.

- Technical support: 7/365 engineer hotline (EN/CN/RU support), rapid email response.

- After-sales: Hassle-free replacement of defective parts, video support, on-site inspection for major clients.

- Documentation: Each order includes test certificates, maintenance guide, and ISO/FDA credentials pack.

Modern hookah smoke consumption demands not only tradition but advanced engineering, safety, and precise customization. Gene sequence hookah delivers leading-edge solutions backed by ISO, FDA, and third-party testing, tailored for pro lounges, hospitality, and industrial use.

- Authoritative manufacturing with proven compliance and rich multinational partnership portfolio.

- Superior technical edge backed by real-world test data and continuous R&D.

- Full transparency from process to certificate, boosting B2B and B2C trust to the next level.

- IMARC Group. “Hookah Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2028.” IMARC report

- Shisha International Forum. “Performance Testing & Hookah Parts Standards (ISO/EN/ASTM)”. Forum topic

- “FDA’s Compliance for Hookah Components,” Journal of Tobacco Regulatory Science Read article

- Gene sequence hookah official tech files: Product site

Previous

This is the first article