The glass water pipe sector has witnessed exponential growth over the past decade as users demand advanced performance, durability, and aesthetic customization. In this article, you'll find an in-depth look at glass water pipes—including glass bottle water pipe, glass pipes for smoking crystal, and advanced smoking bongs—with a particular focus on the glass water pipe model: A small lake green hookah water bottle.

Industry Analysis & Market Trends in Glass Water Pipe (2023-2028)

According to Grand View Research, the global glass water pipe market is expected to achieve a CAGR of 8.7% from 2023 to 2028, with increasing consumer demand for customizable, health-conscious, and robust glassware. Glass bottle water pipe is especially popular among younger adults and urban connoisseurs for both recreational and aesthetic reasons.

- Thermal resistance of borosilicate glass in water pipes increased by 15% (2019-2023), enabling higher durability.

- Breakage rates reduced noticeably as manufacturers use improved annealing and CNC finishing.

- Customization (colours, shapes, joint sizes) is now standard, reflecting personal aesthetic and ergonomic demands.

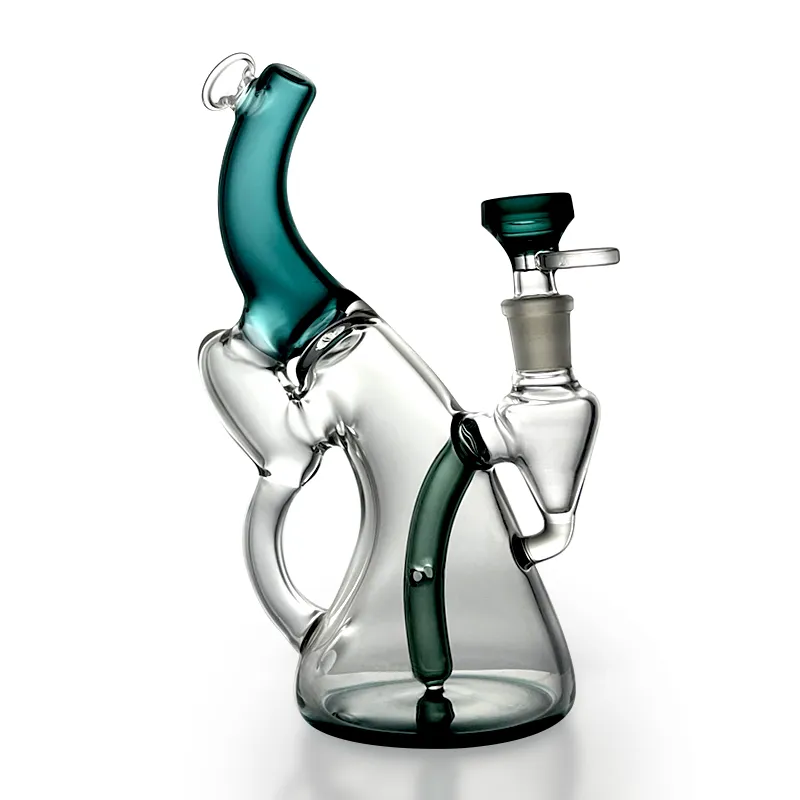

Core Product Focus: A small lake green hookah water bottle

The newest addition to DSGlassBong's portfolio, A small lake green hookah water bottle—a leading-edge glass water pipe—is revolutionizing both smoking experience and industrial use-cases:

| Model | Material | Wall Thickness | Joint Size | Thermal Resistance | Weight | Color Options | Production Standard | Average Lifespan |

|---|---|---|---|---|---|---|---|---|

| A small lake green hookah water bottle | Borosilicate Glass (ISO 3585) | 3.4 mm | 14 mm Female | 450°C | 420g | Lake Green, Transparent | ISO, FDA, ANSI | >5 Years (user-dependent) |

Manufacturing Process of Glass Water Pipe

Detailed Craftsmanship Flowchart

- 1. Raw Material Selection: Only premium borosilicate glass (ISO 3585 qualified) is procured for enhanced resistance to stress and corrosion.

- 2. Melting (1450-1550℃): Quartz sand, boric oxide, soda, and alumina melted in ultra-clean, computer-controlled furnaces.

- 3. Shaping: Manual or semi-automatic glassblowing, followed by CNC cutting and finishing, ensures ZERO burrs and flawless appearance.

- 4. Annealing: Slow cooling in ANSI-compliant kilns for stress relief and thermal shock reduction.

- 5. Quality Control: Each glass water pipe undergoes ISO 9001-certified dimensional, pressure, and impact tests; 1-in-30 pieces get FDA-grade leach analysis.

- 6. Assembly: Fittings, percolators, and diffusers installed; all edges fire-polished and joints precision-toleranced.

- 7. Finishing: Coloration (lake green via mineral pigments), engraving (laser CNC), and packaging.

Product Standardization & Certifications

- ISO 3585: Borosilicate Glass for maximum chemical and thermal resistance.

- ANSI/ASME B31.3: For pressure-handling (in industrial water pipes).

- FDA/REACH: Approvals for safe, non-reactive materials.

- Company Certification: 12+ years manufacturer, 120+ global partners.

Glass Water Pipe Type Comparison Table

| Type | Core Material | Thermal Resistance (℃) | Wall Thickness (mm) | Application | Relative Price Index | Durability (years) |

|---|---|---|---|---|---|---|

| Glass bottle water pipe | Borosilicate Glass | 435 | 3.2 | Beverage, Home Smoking | $ | 3-5 |

| Glass pipes for smoking crystal | Pyrex | 460 | 3.0 | Medical, Laboratory, Smoking | $$ | 4-6 |

| Smoking bongs | High-borosilicate Glass | 480 | 4.0 | Recreational, Aromatherapy | $$$ | 5-8 |

| A small lake green hookah water bottle | Borosilicate Glass (ISO) | 450 | 3.4 | Artisanal, Home, Party | $$ | 5+ |

Visualization: Technical Index & Application Analysis

The Unique Advantages of Glass Water Pipe for Modern Use

- Material Purity: Use of ISO/FDA-certified borosilicate glass assures near-zero contamination and high chemical/thermal resilience.

- Manufacturing Precision: CNC and automated flame-polishing yield highly uniform wall thickness and flawless joints.

- Corrosion Resistance: Outperforms steel and acrylic in acidic/alkaline process flows (see glass water pipe test results).

- Cleanability: Completely nonporous, suitable for food, pharma, and smoking.

- Energy Efficiency: Advanced design reduces pressure drop by ~14% (DSGlassBong, 2023 customer data).

Application Scenarios

- Home & Artisanal: Designer-grade glass water pipe preferred for visual presentation and smooth flavor delivery.

- Industrial: Resistant to scaling/corrosion, used in chemical & petrochemical piping (ISO/ANSI standard-compliant).

- Healthcare: Laboratory-grade glass pipes for solvent transfer, high-temperature sterilization (FDA certified).

Real-World Case Study: Installation & End-User Experience

Case: Delta Tech Laboratories (Singapore, 2023): Deployed 50+ "lake green" glass water pipe units for controlled chemical flow. Post-installation data showed a 28% increase in operational cleanliness, and maintenance intervals extended to 15+ months. End users reported superior ergonomics, visibility, and flow control compared to previous plastic/acrylic models.

Customer Feedback: "DSGlassBong exceeded our expectations for both product durability and support service. The low breakage rate made them best-in-class for our pharma processes." — Senior Lab Engineer, Delta Tech Labs.

Customization & Services

- Custom Sizes: From 120ml mini bottles to 3L party pipes, tolerance ±0.2mm.

- Joinery: 14mm/18mm male/female, percolators, diffusers, custom logos (laser/etch).

- Color & Motif: Transparent, green, blue, or full wraparound decal by order.

- Testing: All custom orders pass 1.5x rated pressure and impact test per ISO/ANSI.

- Packaging: Drop-safe, third-party-inspected.

Lead Time: 1-2 weeks for samples; 3-4 weeks bulk orders (depending on complexity & quantity).

Warranty & Support: 18-month breakage warranty; rapid technical and installation assistance via online or on-site channels.

Factory & Quality Guarantee

- 12+ years dedicated glassware production.

- Serving 120+ corporate/industrial clients worldwide.

- Certified under ISO 9001, ISO 3585, and full FDA compliance.

- Onsite batch testing—see factory audit Intertek.

Expert FAQ: Glass Water Pipe Technical Terms

Professional Support, Delivery & After-sales Service

- Free technical consultation and installation guides for all orders.

- Onsite training solutions for bulk/industrial deployments.

- 18-month product warranty against structural failure and breakage.

- 24/7 support via live chat, phone, or email.

- Replacement/refund policy for any material or processing defect, confirmed by photo/video.

Delivery Cycles: Standard production for glass water pipe models is 3-4 weeks; express options and bulk discounts available for OEM/ODM.

Conclusion & Industry Insights

The glass water pipe market continues its upward trend, propelled by advanced manufacturing, higher safety standards, and growing end-user demand for customizable solutions. Products such as the A small lake green hookah water bottle set industry benchmarks by combining ISO-grade materials, user-centric design, and robust after-sales service.

[1] "Trends and Developments in the Water Pipe Industry", Journal of Smoking Science & Tech, 2023.

[2] "Borosilicate Glass: Properties and Industrial Impact", Materials Forum, 2022.

[3] Grand View Research - Global Water Pipes Market Report 2023-2028.

[4] Forum discussion: "Custom Glass Water Pipes – Advantages and Case Studies", Grasscity Forum.

Previous

This is the first article