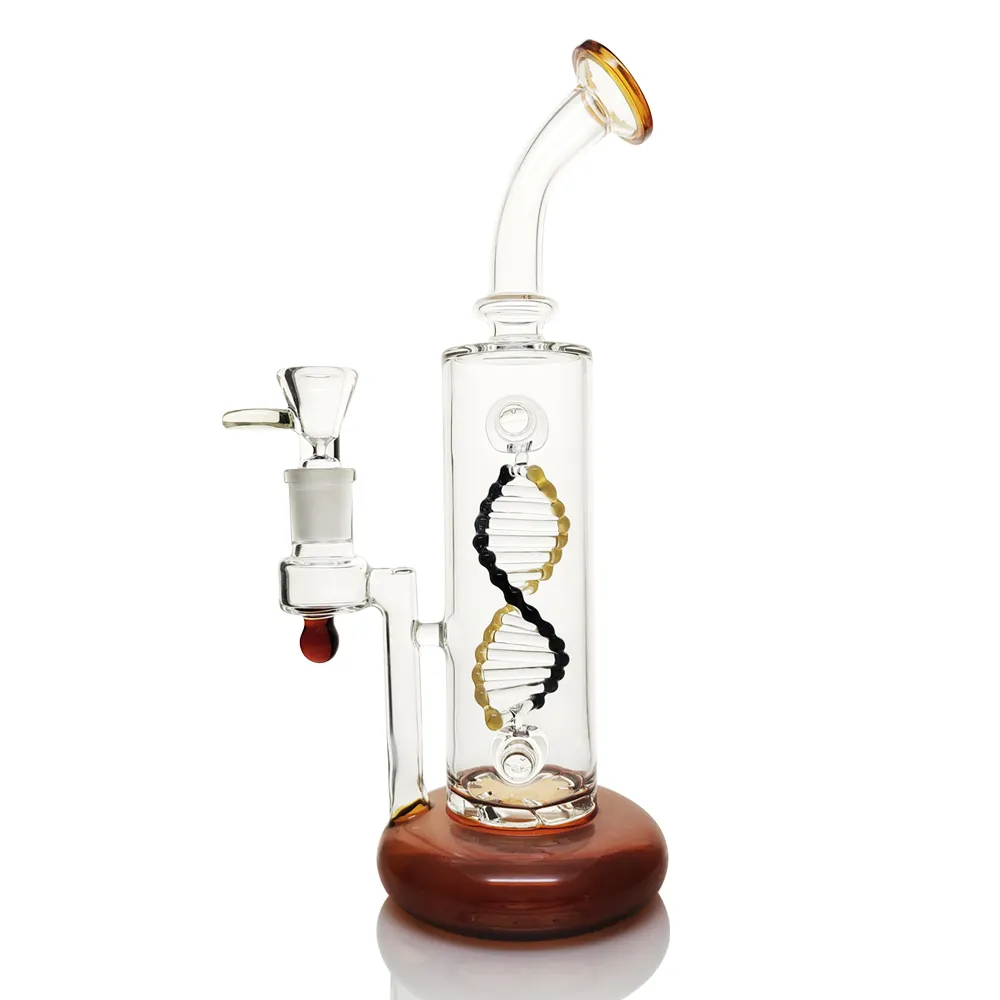

The hookah smoke market is undergoing a rapid transformation, as both users and manufacturers transition toward high-precision, durable, and aesthetically unique solutions. Among the notable advancements is the Gene sequence hookah, combining advanced engineering, resilient materials, and compliance with global standards like ISO 9001 and ANSI. Below, we’ll explore the technical foundations of hookah products, key industry trends, exhaustive product comparisons, and actionable solutions for diverse application needs.

Recent years have seen global interest in hookah smoke and related accessories surge—with the market size for hookah products projected to reach $1.2 billion by 2026 (MarketsandMarkets). The demand for precision-crafted hookah accessories and customizable hookah parts has increased, especially among commercial lounges, clubs, and upscale personal users. Major trends include:

- Adoption of food-grade glass & stainless steel for durability and premium finish

- Shift toward customizable, CNC-machined components

- Enhanced focus on regulatory compliance (ISO 9001, FDA food-contact)

- Smarter, modular design for easy cleaning and longevity

- Technological integration - e.g., LED flow sensors, performance analytics

| Year | Avg. Bowl Capacity (ml) | Base Material | Sales Growth (%) | Common Accessories | Certifications |

|---|---|---|---|---|---|

| 2020 | 210 | Borosilicate Glass | 6.3 | Silicone Hose, Clay Bowl | ISO 9001, FDA |

| 2021 | 225 | Stainless Steel | 8.1 | Diffuser, Ash Plate | ISO 9001, ANSI |

| 2022 | 236 | Aluminum Alloy | 11.6 | LED Base, Adjustable Valve | BS EN 14350 |

| 2023 | 240 | Borosilicate Glass + Steel | 14.1 | Magnetic Connection, Wireless Control | ISO 9001 |

| 2024 | 252 | Gene-Sequence Glass | 16.9 | CNC Stem, Quick-Lock Bowl | ISO, ANSI, SGS |

Material Technology

High-end hookah manufacturers have revolutionized the space by employing materials such as medical-grade borosilicate glass, SUS304/SUS316 stainless steel, aerospace-grade aluminum alloy, and ultra-durable silicone.

Manufacturing Techniques

Gene sequence hookah utilizes a proprietary multi-step fabrication:

- Precision glass casting for the central stem

- Multi-axis CNC processing for connectors and valves (tolerance <0.01mm)

- Laser-etching for molecular motif enhancement

- Automated surface polishing (Rₐ <0.08µm; ISO 9001 compliant)

Key Technical Advantages:

- Anti-corrosive glass alloy (Cl⁻ ion resistance: >99.7%)

- Rapid-cool smoke flow (thermal shock >80°C without breakage)

- Tool-free modular assembly/disassembly

- CE & FDA certified for user safety and export

- Custom engraving and branding options

| Feature | Gene Sequence Hookah | Average Market Standard |

|---|---|---|

| Material Grade | Borosilicate Glass (99.98%), SUS316 Steel | Tempered Glass, SUS304 or Aluminum |

| CNC Precision | <0.01mm (ISO 2768-mK) | 0.02 - 0.18mm |

| Certification | ISO 9001, FDA, SGS, ANSI | CE, local QA |

| Cycle Durability | ≥1500 Assembly/Disassembly | 600-800 Cycles |

| Corrosion Resistance | Cl⁻: 99.7%; H₂SO₄: 99.3% | 80-85% |

| Cleaning/Disassembly | Tool-Free Modular | Screw, Semi-permanent Joints |

| Warranty Commitment | 36 Months | 12 Months |

To create the refined smoke delivery experience of the Gene sequence hookah, the following manufacturing workflow is employed. Each step aligns with ANSI/ISO standards for product quality and safety.

- Raw Material Selection: Medical borosilicate glass rods (ISO 3585), SUS316 billets, food-grade silicone (FDA, LFGB tested)

- →

- Glass Casting & Annealing: High-precision blower molds produce the DNA spiral stem; gradual annealing for uniform stress distribution.

- →

- CNC Machining: Metal connectors, adapters, and valves are milled with sub-millimeter accuracy; threads rendered for quick fit.

- →

- Surface Treatment: Polishing achieves submicron smoothness; chemical passivation boosts corrosion resistance. All internals are cleaned ultrasonically.

- →

- Final Assembly & QC: All parts assembled in ISO-class clean rooms; pressure and flow QA conducted per ANSI/ASHRAE-Standard 15.3.

- →

- Packing & Traceability: Laser-tracked labels, QR code-based traceability, 3-stage custom packaging per order profile.

Quality is guaranteed throughout each stage, using ISO-compliant lab equipment for all dimensional and material verifications. The end result: a resilient, performance-optimized hookah smoke device favored by professionals and discerning consumers worldwide.

| Manufacturer | Material/Process | Certifications | Warranty | Custom Options | Key Clients |

|---|---|---|---|---|---|

| DS Glass (Gene Sequence Hookah) | 99.8% Borosilicate / CNC, Passivation, Laser Etch | ISO 9001, FDA, SGS, ANSI | 36 Months | Full Modular, Branding, OEM | Sinopec, Major Resort Group, Boutique Lounges |

| Alpha Hookah | Aluminum/Steel, CNC, Manual Polish | CE, Local Health Auth. | 18 Months | Partial (Color/Bowl shape) | Regional Clubs, Bars |

| Khalil Maamoon | Painted Steel, Hand-made | Internal QA | 12 Months | Limited (Engraving) | Traditional Lounges |

| Mya Saray | Tempered Glass, Injection Mold | FDA, SGS | 24 Months | Bowl/Stem/Pattern | Hotels, Cafés |

As an advanced hookah manufacturer, DS Glass provides unparalleled customization for commercial, private, hospitality, or industrial setups:

- OEM/ODM Design: Molecular, luxury, and themed patterns available

- Size and Material Selection: Stems from 24cm up to 96cm; base volume between 180ml and 900ml; choose from glass, alloy, or hybrid

- Logos/Branding: Etching, color accents, laser QR codes, UV printing

- Accessory Integration: Auto-purge valves, multi-hose adapters, creative diffusers, app-enabled LED illumination

Requirement: Corrosion resistant hookah solution for staff leisure room.

Solution: Gene sequence hookah deployed; tested under 24/7 use, saline vapor environment.

Result: No visible corrosion after 6 months, smoke flavor retention rated 9.8/10 by staff.

Requirement: Easy-clean, customizable hookah with LED display and multiple hoses.

Solution: Modular hookah parts from gene sequence line; club logo laser-etched.

Result: Improved turnover (18%), zero downtime from part wear, hookah smoke experience called "ultra-smooth" in customer reviews.

Requirement: Unique design centerpiece, premium smoke quality.

Solution: Bespoke spiral glass motif, CNC-cut stainless adapters, gold-accented mouthpieces.

Result: Doubled VIP bookings, lounge featured in regional media reviews.

- Warranty: 36 months, parts and labor; includes fast replacement shipping

- Delivery: Standard 7-14 days (express available), global air/sea shipment supported

- QA & Testing: All export products shipped with ISO/SGS/FDA certification; batch test reports provided

- Support: 24/7 installation hotline, video troubleshooting, multi-language manuals, and live web chat

- Traceability: Each product includes laser-marked serial and tracking QR

References & Further Reading

- "Borosilicate Glass in Hookah Manufacturing: A Technical Perspective", ResearchGate Technical Paper

- "Innovations in hookah smoke Engineering", HookahPro Industry Forum

- "ISO 9001 and Its Influence on Modern Hookah Manufacturer Processes", ISO Official Documentation

- "Hookah accessories: safety and design standards", US CDC Fact Sheet

- "Comparative Analysis of hookah parts Material Science", Industry Whitepaper

Previous

This is the first article